Need further assistance?If you are looking for some additional information or support, feel free to get in touch with our packaging experts & sales team.

CORB-03

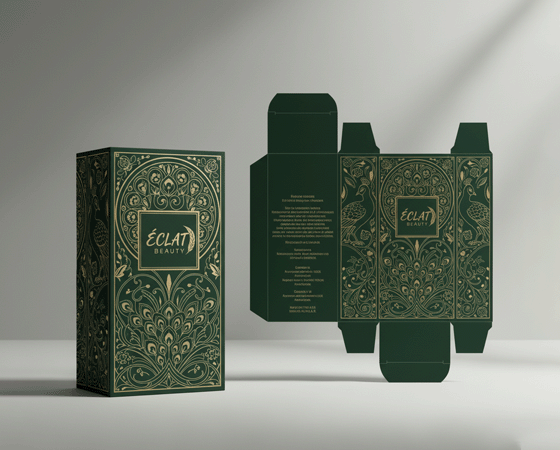

Corrugated Reverse Tuck End Boxes

Corrugated reverse tuck end boxes feature opposite folding flaps on the top and bottom, they close securely without tape or glue while providing fast manual assembly.Fully Customizable Cardboard Boxes Tailored to Your Unique Needs

Product OverviewTop flap that tucks from rear to front and bottom flap that tucks from front to rear | Board StrengthTypically made with E-flute or B-flute corrugated board (350–600 gsm) | CustomizationAvailable with auto-lock bottoms, display windows, or tear tabs. |

Material OptionsMaterials are selected to balance print finish and mechanical performance. | White Coated BoardSmooth, print-optimized surface for high-resolution branding and labeling. | Kraft Corrugated BoardDurable, natural-toned substrate for eco-friendly products. |

Color & PrintingAll RTE boxes support flexographic, offset, and digital printing. | CMYK OffsetUsed for retail-grade printing with intricate graphics and gradients. | Flexographic PrintingDurable and economical for high-volume, single-color branding. |

What to Know Before Designing Mailer Boxes with Tear Strip

The performance of reverse tuck end boxes depends on board thickness, crease accuracy, and flap alignment. Even a minor deviation can affect how smoothly the flaps fold and lock. Choosing the right GSM and grain direction ensures the box closes neatly without cracking.

StructureSecurer Closure MechanismComprises front and back films sealed along three sides. The fourth side remains open for filling and final heat seal.

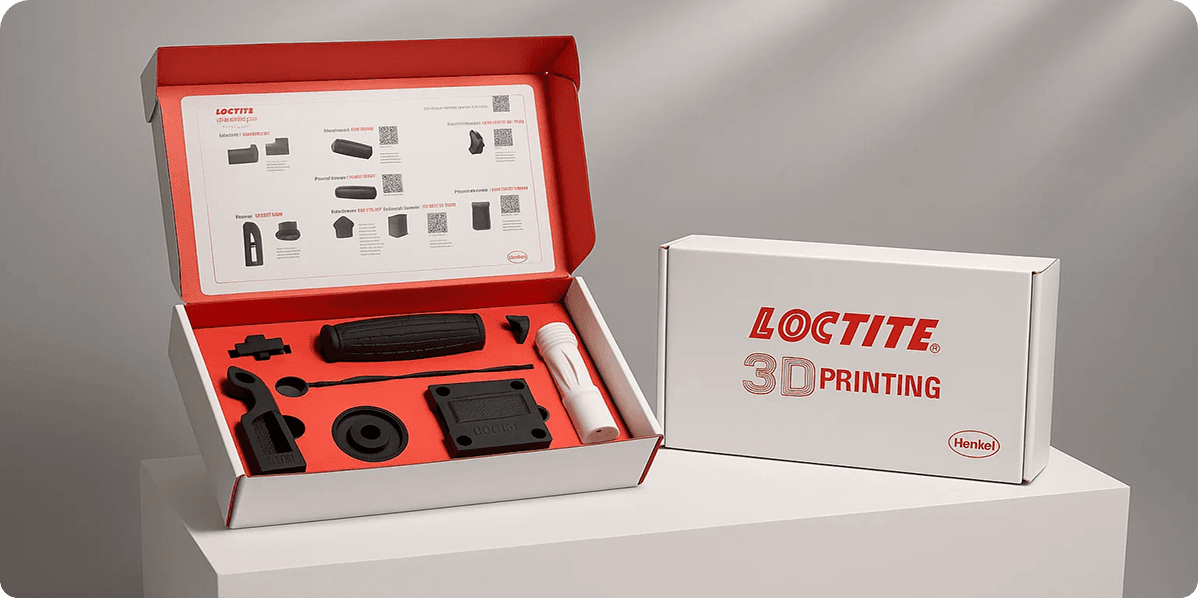

Construction TechniquesSupport Inbound LogisticsThe flat-pack design helps reduce storage needs and shipping costs, freeing up valuable space and improving your logistics efficiency

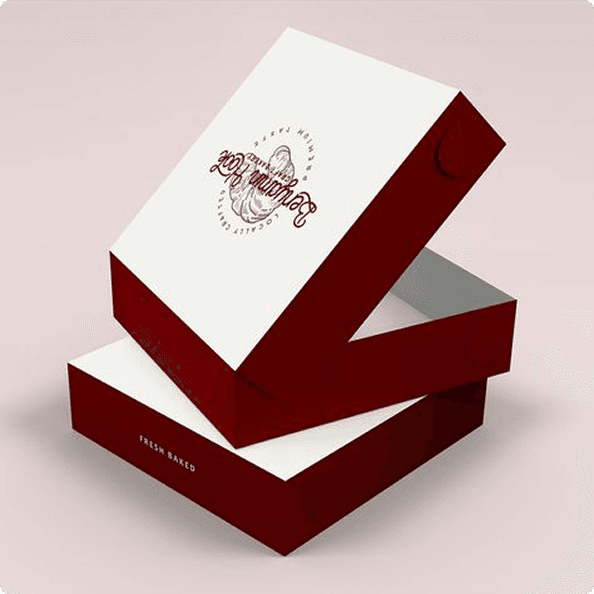

Design & BrandingProtection with AestheticsThe compact design fits products snugly, while the outer surface acts as a surface for important branding and product information

Making Your Brand Unforgettable

Need Help Designing Your Cardboard Boxes?

We provide free in-house design support

Frequently Asked Questions

Get answers to common questions about custom rigid boxes, or visit our Help Centre for further information.What are reverse tuck end (RTE) cardboard boxes?

Reverse Tuck End cardboard boxes feature top and bottom flaps that tuck in the same direction (usually to the back). This closing mechanism gives folding cartons a clean, professional appearance, making them an excellent choice for retail packaging.

How are reverse tuck end boxes different from straight tuck end boxes?

As the name implies, while the top and bottom flaps tuck in the opposite direction in an RTE box, flaps in a straight tuck end box close on the same side, which makes them more suitable and cost-effective for slightly bulkier or heavier products.

Are reverse tuck end cardboard boxes easy to assemble?

Yes! They come pre-glued and ship flat, so you can fold and pack them within seconds without needing tape or staples.

Can reverse tuck end boxes handle heavy items?

RTE boxes and other folding cartons are made with cardstock. They are typically used for individual product packaging where the product volume and weights are low. For heavier and bulkier products, we recommend using corrugated cardboard. You can find out more about corrugated boxes here. (Corrugated Boxes / Mailer boxes landing page link).

Can I add a window cut-out to my reverse tuck end cardboard boxes?

100%!! With our custom cardboard boxes, you can choose from a wide range of customizations, including a die cut or PVC cut-out for increased product visibility.