Need further assistance?If you are looking for some additional information or support, feel free to get in touch with our packaging experts & sales team.

CORB-06

Corrugated Straight Tuck End Boxes

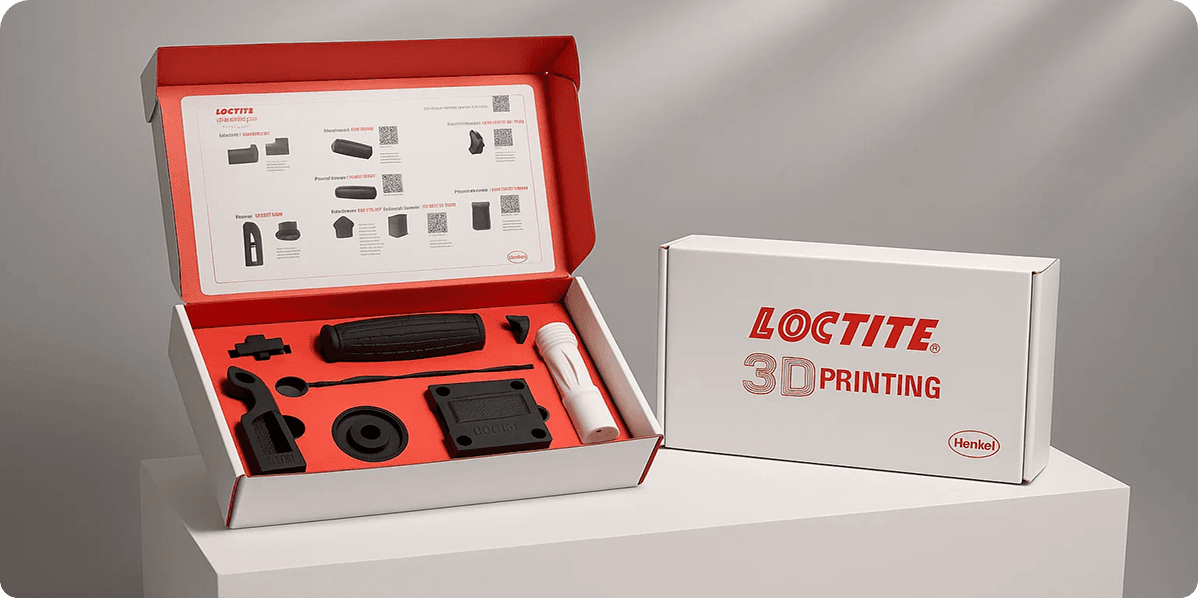

Corrugated straight tuck end boxes feature clean front-panel presentation with dependable closure strength. Both the top and bottom flaps tuck in the same direction.Fully Customizable Cardboard Boxes Tailored to Your Unique Needs

Product OverviewStraight tuck end (STE) boxes feature dual same-direction tuck closures | Board StrengthManufactured using E-flute, F-flute, or micro B-flute corrugated board (350–550 gsm) | CustomizationDie-cut display windows, hang tabs, or locking mechanisms |

Material OptionsEvery board type is selected for surface consistency andKraft Corrugated Board print adaptability. | Dual-Layer LinerboardOuter white liner with inner kraft backing for strength and aesthetic balance. | Kraft Corrugated BoardHigh tear strength and a tactile matte finish for eco-branding. |

Color & PrintingAll straight tuck end boxes support flexographic, offset, and digital printing. | Offset LithographyEnsures crisp, high-definition color reproduction across all visible panels. | Flexo or Digital PrintIdeal for bulk or limited runs where turnaround time matters more |

Technical Aspects of Designing Straight Tuck End Boxes

These boxes require precision in crease alignment, tuck flap fit, and closure tension determines how professional your straight tuck end box looks and performs. The grain direction of the board should follow the tuck motion to prevent cracking or resistance during folding

StructureClean Closure, Durable BuildTop and bottom flaps fold in the same direction, providing a neat, unified appearance with reinforced side walls for rigidity.

Material StrengthChoose Stability That Fits Your Product400–600 gsm board is ideal for standard retail goods, while E-flute corrugated supports heavier items without compromising on presentation.

Folding & AssemblyEngineered for Precision and SpeedStraight tuck boxes assemble quickly, fold smoothly, and maintain shape across multiple openings, making them ideal for both manual and automated production lines.

Making Your Brand Unforgettable

Need Help Designing Your Folding Cartons?

We provide free in-house design support

Frequently Asked Questions

Get answers to common questions about custom rigid boxes, or visit our Help Centre for further information.How do straight tuck end boxes differ from reverse tuck boxes?

In straight tuck boxes, both flaps tuck in the same direction, providing a smooth front panel, while reverse tuck boxes have opposing flaps for faster closure.

Can straight tuck boxes include windows or inserts?

Yes — you can customize cardboard boxes with die-cut windows, transparent films, or inserts for secure product placement.

Are these boxes eco-friendly?

Absolutely. Made from recyclable, FSC-certified paperboard, and printed with eco-conscious inks.