Need further assistance?If you are looking for some additional information or support, feel free to get in touch with our packaging experts & sales team.

CFB-01

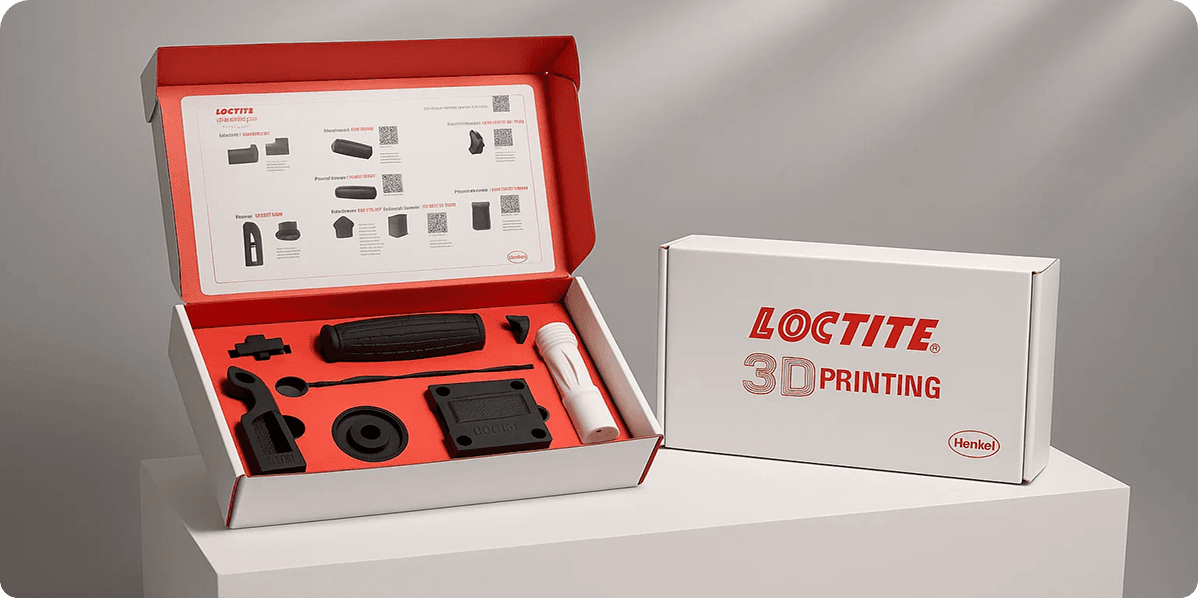

Sleeve and tray boxes

Sleeve and tray boxes are two-piece folding cartons featuring a slide-out tray enclosed by an outer sleeve. Designed for food items, cosmetics, tech accessories, and premium retail packagingFully Customizable Cardboard Boxes Tailored to Your Unique Needs

Material CompositionManufactured using C1S/C2S paper, kraft board, or duplex board | ThicknessComes in the option of 350–600 gsm thickness. | Fit & ToleranceReinforced board for stability and load-bearing |

Functional FeaturesPerfect for flat-packed delivery with easy assembly. | Available StylesStraight-sleeve, partial-sleeve, double-wall tray, and glued-end tray | ClosureFriction fit, glued side sleeve, or thumb-cut for easy tray removal. |

Color & PrintingSupports offset printing up to 8 colors with full bleed and precision registration. | Offset LithographyEnsures crisp visuals and accurate alignment between sleeve and tray | FinishesMatte/gloss lamination, spot UV, foil stamping, embossing, & debossing |

Designing the Perfect Customized Sleeve & Tray Box

When designing customized cardboard boxes in sleeve style, precision in sleeve fit, board thickness, and crease tolerance determines how well your tray slides and aligns. From the folding pattern to the outer wrap tension, every millimeter affects both usability and presentation

StructureTwo-Piece Construction for Smooth FunctionalityEach box includes a folded inner tray and a wraparound sleeve. The tray is die-cut with glued or tuck-end flaps, while the sleeve is joined from one edge to form a smooth enclosure. The overlap ratio and fold depth control how easily the tray slides.

Material & Board OptionsPaperboard Precision, Tailored for StrengthTypically produced using 350–600 gsm paperboard, coated on one or both sides. Boards like SBS (Solid Bleached Sulfate) or CCNB are preferred for premium-grade sleeves, while kraft or recycled boards are ideal for sustainable brands.

Finishing & DetailingDefining the Unboxing ExperienceFrom soft-touch lamination and embossing to die-cut sleeves with finger notches or windows, every finish elevates the reveal. Custom coatings prevent friction, ensuring the tray glides smoothly while keeping artwork vibrant and scuff-free.

Making Your Brand Unforgettable

Need Help Designing Your Cardboard Boxes?

We provide free in-house design support

Frequently Asked Questions

Get answers to common questions about custom rigid boxes, or visit our Help Centre for further information.What GSM is best for sleeve and tray boxes?

Generally, 400–500 gsm is ideal for retail packaging. Lighter boards can be used for compact products, while 600 gsm adds extra strength for luxury packaging.

Are sleeve boxes shipped flat or pre-assembled?

Cardboard packing box are typically shipped flat to save space, with easy folding and gluing during assembly. This reduces shipping cost and optimizes freight volume.

Can I add inserts or compartments inside the tray?

Yes. Die-cut paperboard or foam inserts can be added to secure fragile or multi-piece products in cardboard boxes.

Are these boxes eco-friendly?

Yes. Made with recyclable and FSC-certified paperboards, and printed with soy-based inks upon request.